Hot Weather Incoming – Are You Ready? Stock up now on essentials to beat the heat.

Pressure Treated Timber

Use Classes

There are 4 different Use Classes of timber; beginning with 1 being the least protective and rising to 4 being the longest lasting and most resilient of treatments. All of our timber products will have been treated to a minimum of Use Class 3 treatment, however, Use Class 4 (UC4) is the industry standard for ground contact timber. We have outlined the treatment method our UC4 timber is submitted to.

Kiln Drying and Pressure Treatment

The Preservative used in UC3 and UC4 timber is the same, apart from the UC4 preservative being a higher concentration. How the timber is prepared before treatment is the main differential between the Use Classes. For UC4 timber, to allow the preservative to penetrate deeper into the timber, it is kiln dried to 28% moisture content (and in some cases less). Moisture content of timber is defined as "the comparative weight of the moisture in the timber against the completely oven dry weight". As a result you can have a moisture content of over 100% as when a tree is initially cut down, the water content can weigh more than the wood content.

To understand the benefits of kiln drying, an easy comparison to make is thinking of the timber as a sponge. A dry sponge absorbs water very easily, however, it is very difficult for a water saturated sponge to take on any more water. When trees are logged they are saturated with water. Natural drying is a long process and can vary in effectiveness. The Kiln accelerates the drying processes and removes a significant amount of moisture content from the timber. The Kiln can take up to 16 hours to reach the correct temperature, after which the timber is treated for 5-7 days to achieve a moisture content of 28%. The timber now more accurately reflects the dry sponge rather than the saturated sponge, meaning it is ready for the preservative treatment.

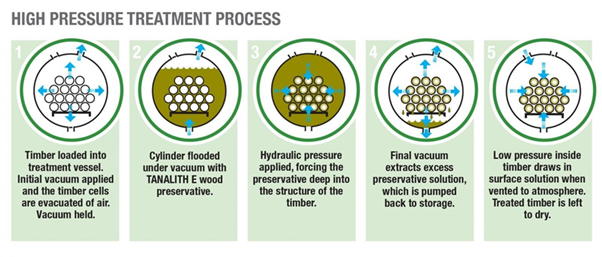

High Pressure Treatment Process

Stage 1 - Kiln dried timber is loaded into treatment vessel

Stage 2 - A Vacuum is applied to the vessel, removing all air from the timber, and held.

Stage 3 - Vessel under vacuum is flooded with preservative

Stage 4 - Pressure applied to vessel, forcing preservative to penetrate into timber

Stage 5 - Final vacuum applied, withdrawing any excess preservative from timber

Stage 6 - When removed from the vessel the low pressure inside the timber draws in any surface solution. Timber is left to dry.

After Treatment

Treated timber will be left for a minimum of 48 hours to dry before being transported. It is important to remember that the treatment process creates a seal on the timber and any cuts or incisions will break this seal. If treated timber is cut it should be treated with an end coat. If possible no parts of timber that have been cut should have ground contact.